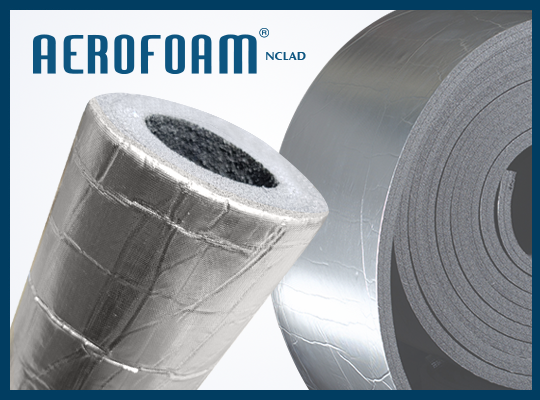

Aerofoam® XLPE N-CLAD system contains sheets, rolls, tubes, and tapes. Insulation foam is made of closed-cell crosslinked polyolefin coated with a strong and durable jacketing, which replaces costly and complex aluminum, zinc-plated steel or stainless steel sheet facings. The foam has excellent properties in terms of condensation control, mechanical and chemical resistance, long term thermal block and sound absorption.

Aerofoam® XLPE N-CLAD sheets, rolls, tubes, and tapes have very good dimensional stability, showing a “memory effect” (they tend to come to their original shape after being compressed).

Aerofoam® XLPE N-CLAD sheets, rolls, tubes, and tapes are an economical solution compared to the expensive and labor-intensive aluminum, zinc-plated steel or stainless steel cladding. Some of the benefits are the following: less-skilled labor required, fast installation (50% faster than metal cladding), lightweight material, safe to use (N Clad jacketing – no safety equipment required), easy to cut, no drill required (light punching tool is enough), no power tools required, easy and light to lift and carry, N Clad jackets can be cut on-site without waste (on a cutting table), space-saving storage.

For more information, please download the Aerofoam® XLPE Insulation Tubes catalogue below.

APPLICATIONS

- Indoor and outdoor pipes, air ducts, and tanks

- Industrial pipelines (Chemical, Pharmaceutical, Oil and Gas, Food, and Beverages).

PROPERTIES

- UV and corrosion resistance

- Fire rated “CLASS O” as per BS 476 Parts 6 & 7

- Very low water vapor permeance (0 perms)

- Water and water vapor resistant

- Water vapour diffusion factor > 60000.

- High thermal efficiency (λ24˚ C = 0.034 W/mK; λ46˚ C = 0.036 W/mK)

- Wide temperature range (from -80˚ C to +105˚ C)

- Chemical resistance – Resistant to most chemicals (sodium, silica, fluoride, chloride, etc.)

- Antibacterial & antifungal

- Environmental friendly – ODP = 0 and GWP < 5

- Very low VOC emission level ( < 4 µg/m2/hr in 24 hours)

- Good mechanical resistance

- Easy and fast to install

- Aesthetical look.